Robust refrigeration technology for the navy, cruise ships and ferries: Ship ahoy with MARENUM!

Reliable and efficient chillers have long been part of the basic equipment of modern ships. However, special conditions apply on the water that differ from the usual requirements on land. Daniel Keller, Head of Sales & Business Development at ENGIE Refrigeration, explains what characterises refrigeration technology for the navy, cruise ships and ferries and what advantages our MARENUM chillers offer for various types of ships. He also provides exciting insights into three reference projects.

Daniel, why are chillers indispensable on the high seas?

Daniel: This varies depending on the type of ship: on cruise ships, refrigeration technology ensures the comfort of thousands of passengers, for example by providing demand-orientated cooling for cabins, restaurants, storage and technical areas. In the navy, refrigeration technology makes a significant contribution to safety - whether by cooling electronic systems or sensitive equipment. If operations do not function properly, this not only has an economic impact, but also an operational one.

What special requirements must refrigeration technology fulfil on naval vessels, cruise ships or ferries?

Daniel: Reliability and operational safety are paramount. This is because chillers have to function on the high seas under changing environmental conditions. Be it in high humidity, salty ambient air or strongly fluctuating loads. Energy efficiency also plays a decisive role in the shipbuilding industry, as every kilowatt hour saved directly reduces fuel consumption. This in turn reduces operating costs and benefits the environment.

How does MARENUM, the chiller from ENGIE Refrigeration specially designed for marine applications, fulfil these expectations?

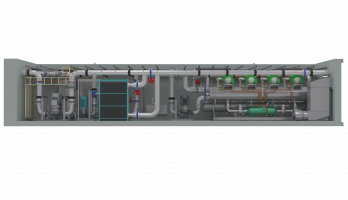

Daniel: Our MARENUM chillers offer high cooling capacity in a small space. Optimised for use in maritime environments, our refrigeration technology meets the highest safety standards in the navy, on cruise ships and on ferries. Seawater-resistant high-performance finned tubes and a controllable three-way valve ensure trouble-free operation - at seawater temperatures from -2 to +36 degrees Celsius. High energy efficiency can also be relied on thanks to modern oil-free compressor technology.

Interesting - our readers are certainly curious about specific project examples in which MARENUM has proven itself.

Daniel: I'm happy to tell you about that! Regardless of the type of ship, MARENUM demonstrates to our customers worldwide that our chillers are predestined for use on the high seas. For example, our refrigeration technology is currently demonstrating its consistent operational reliability and efficiency in a marine project . MARENUM also fully meets the requirements of our customer - low noise and vibration values, shock resistance, fulfilment of performance criteria for electromagnetic compatibility (EMC) and short maintenance intervals.

And how is MARENUM being used in civil shipping?

Daniel: Also reliable and efficient. For example, our refrigeration technology is currently ensuring a stable refrigeration supply on two new cruise ships in quadruple design with ten megawatts of refrigeration capacity per ship. In addition, two MARENUM chillers with a cooling capacity of 2.4 megawatts per ferry are also convincing on several ferries with a length of around 190 metres. In both projects, our refrigeration solutions scored highly in terms of energy efficiency and an outstanding maintenance concept.

Your conclusion: Why are efficient chillers not only relevant on ships today, but also in the future?

Daniel: Firstly, I would like to emphasise that operational safety and modern, flexibly adaptable technologies will always be success factors in demanding environments such as ships. The shipbuilding industry is also under increasing pressure to constantly reduce its emissions. Our energy-efficient chillers make an important contribution to this. There is also a trend towards hybrid and fully electric ships. All technical systems must be highly efficient and intelligently networked. As MARENUM fulfils all these requirements in an exemplary manner, I am convinced that our refrigeration technology will continue to be an integral part of naval vessels, cruise ships and ferries in the future.