Tailor-made solution for data centres: 16 water-cooled QUANTUM chillers in a container ensure whisper-quiet operation and maximum efficiency

Jürgen, what makes this data centre project special for ENGIE Refrigeration?

Jürgen Martin: Our team has been supporting customers from the international data centre industry for many years. We are applying our outstanding expertise to this project in a special way: Our customer is one of the best-known and largest general contractors for data centres in Europe; we are all the more pleased to have convinced this company of our products and solutions. Together with a global provider of planning and consulting services for high-performance buildings and infrastructure facilities, we are currently developing a highly efficient turnkey data centre for an international IT company in the Netherlands. The tasks are clearly distributed in order to achieve the best possible project result: While we are planning the project in close coordination with our customer and supplying the cooling for the data centre, the customer is responsible for the building construction, technical expansion and optimised production planning as the general contractor. The sophisticated concept and the successful cooperation between the project participants make the project so unique.

What technical specifications are at the forefront of the project?

Jürgen Martin: First and foremost, our customer attaches great importance to a short, stable supply chain and maximum cost-effectiveness. The city of Amsterdam, where the new data centre is being built, also requires a very low sound power level of 70 decibels. To put this into perspective, this means that there is a sound pressure level of 43 pascals within a radius of ten metres, which is roughly comparable to a quiet conversation. In addition, the project is based on demanding building specifications regarding the dimensions of our turnkey cooling solution. According to the building permit, this must not exceed a height of 2.80 metres. The special requirements of the data centre industry, which we have already mastered in numerous projects, should also not be forgotten. These include permanent chiller availability, a short start-up time after a power failure thanks to fast restart technology, maximum efficiency and the use of innovative software technology.

What technical solution did ENGIE Refrigeration use to meet these requirements?

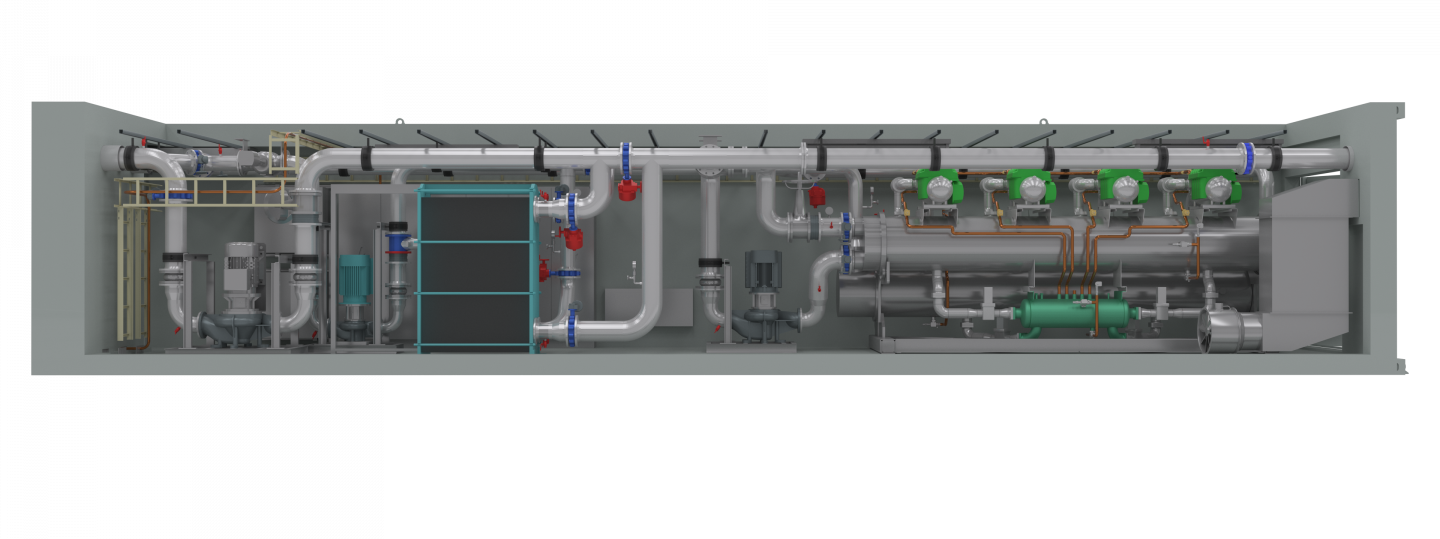

Jürgen Martin: As a market pioneer for water-cooled chiller series with outstanding efficiency, QUANTUM Water is the perfect choice for the project. The new data centre is equipped with 16 of them - and impresses with concentrated power totalling 36.8 megawatts of cooling capacity. Each QUANTUM is installed in a GENIUM cooling container that fulfils all the requirements of the DIN EN 378 standard. Technically, the container in the data centre guarantees voltage isolation in the event of a power failure. The built-in ventilation system is explosion-proof and also guarantees optimum sound insulation thanks to sound absorbers. The future-proof and long-term available refrigerant R-1234ze provides the ideal properties for the container in the data centre. This also qualifies as a suitable option against the background of the F-Gas Regulation. The finished container solution is scheduled for delivery by the end of October 2024.

What specific advantages does the customer benefit from? And what is special about the container solution?

Jürgen Martin: With our QUANTUM chillers installed in the GENIUM container, the general contractor receives a turnkey high-end solution at a fixed price with maximum efficiency - and with defined delivery times. This means he can rely 100 per cent on a high level of project security. Thanks to our container solution, maximum efficiency, operational reliability and performance are also guaranteed for the cooling supply in the data centre. Finally, I would like to emphasise the teamwork at ENGIE Refrigeration: Many colleagues from various departments, including Development, I&C, Application Management, Product Management and Sales, are contributing to the success of this project. Thanks to our strong expertise in all these areas, we offer the customer real added value.

How far is QUANTUM in the GENIUM container interesting for similar applications?

Jürgen Martin: Our container solution is clearly not only suitable for other data centre operators, but also for various other industries. This is because it offers the ideal technical prerequisites for sensitive applications thanks to its whisper-quiet design and high efficiency. Particularly in urban centres, strict noise regulations apply with high performance requirements. As we have demonstrated in numerous projects in the data centre sector, for example in the cooling and heating supply for no less than ten data centres in Germany's metropolitan areas, our product portfolio is characterised by a high degree of versatility and maximum flexibility. In addition, QUANTUM chillers in a GENIUM container opens up promising potential for other sectors, as it enables the construction of a cooling centre without having to erect a new building. This saves planning effort and construction time and reduces costs - arguments that, in addition to efficiency and operational reliability, are definitely unbeatable for many operators.

Jürgen, thank you very much for talking to us!