Large-scale heat pumps as pioneers for energy transition in industry

Industry faces a double challenge: rising energy costs, high CO₂ taxes and regulatory requirements on one hand, and technically demanding processes on the other. At the same time, two-thirds of industrial energy flows into nothingness as unused waste heat – while fossil fuels are imported at a cost of billions. Andreas Kuhn, Key Account Manager Industrial & Commercial Heating at ENGIE Refrigeration, explains in an interview how large-scale heat pumps can help solve this dilemma and drive forward the energy transition in industry.

Andreas, why is process heat such an important topic for the energy transition in industry?

Andreas: The figures speak for themselves: 86 per cent of industrial process heat in Germany is still based on fossil fuels such as gas, coal or mineral oil. This is not only an enormous climate problem, but above all a massive production risk for companies. This dependency means uncertainty in energy prices, rising CO₂ costs and growing regulatory pressure. At the same time, we know that two-thirds of total industrial energy demand is accounted for by process heat – and that a large proportion of the waste heat generated in this process is released unused into the environment. At ENGIE Refrigeration, we see this as a hidden treasure that we want to unlock. For industrial companies in particular, this means that those who act now and invest in renewable heating solutions can not only mitigate risks, but also secure competitive advantages.

What specific heating solutions does ENGIE Refrigeration offer for the industry?

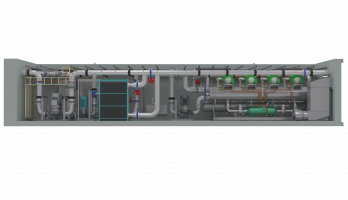

Andreas: We have developed a broad portfolio of large industrial heat pumps that are used extensively and reliably by our customers in industrial applications. We offer a range of technologies: our thermeco2high-temperature heat pumps achieve useful temperatures of up to 110 degrees Celsius and operate with the natural refrigerant CO2. SPECTRUM Water heat pumps deliver over 70 degrees Celsius with oil-free technology, while our QUANTUM with Green Heat Recovery performs at useful temperatures of up to 57 degrees Celsius. For lower temperature ranges up to 50 degrees Celsius, we have PENSUM Air Reversible Heat and AMONUM Water in our portfolio, which run on sustainable or natural refrigerants. All large industrial heat pumps from ENGIE Refrigeration are based on sophisticated technologies that have long proven themselves in practice and can be combined effectively with sustainable energy sources.

What energy sources can companies tap into with large heat pumps?

Andreas: The energy is literally on our customers' doorsteps; they just need to use it strategically. We distinguish between natural heat sources and industrial waste heat. Water, geothermal energy and ambient air provide us with free energy from nature and contribute to the energy transition in industry. At the same time, many processes waste valuable heat every day, whether in data centres, drying plants or compressed air generation. Our large heat pumps are designed to use this diversity efficiently and safely. The question for companies is not whether they have a heat source. The question is: when will they start using it strategically?

Can you give us some practical examples of how ENGIE Refrigeration has used these heat sources in concrete terms?

Andreas: Of course. One of our current projects is in the chemical and pharmaceutical industry, where we have integrated geothermal energy as a strategic energy source. Here we were dealing with seasonal demand: large amounts of waste heat in summer, high heat demand in winter. As a solution, we used a geothermal field as a huge thermal water storage facility. In summer, excess heat is stored in the ground and in winter it is released as a source for the large heat pumps. We integrated three SPECTRUM Water heat pumps into the geothermal field to cover both heating and cooling requirements. This gives our customer important advantages: a stable supply, reduced operating costs and a clear sustainability edge over the competition.

And what project experiences can you share with us in the field of waste heat?

Andreas: In this context, I would like to present the use of waste heat in a large Swiss slaughterhouse as an example. Here, we installed three thermeco2high-temperature large heat pumps, which have been in operation since 2011 and recover low-temperature waste heat from the refrigeration system, the room air and the compressed air generation. The total heating output is 801 kilowatts, with a COP of 3.4. What makes this special is that, thanks to our heating solution, we have reduced the heat requirement from steam generation by 2,590 megawatt hours per year compared to conventional methods, saving around 510 tons of CO₂ per year – without disrupting operations or compromising hygiene requirements.

That sounds like a considerable investment. How can companies finance such projects?

Andreas: This is where EEW subsidies come into play, providing real leverage for the energy transition in industry. There are two particularly relevant modules: Module 2 promotes process heat from renewable sources with a maximum subsidy rate of up to 60 per cent of the total investment costs. It is important that at least 50 per cent is used for process heat. Module 4 supports the energy and resource-related optimisation of plants with a focus on decarbonisation. Here, up to 55 per cent of the additional investment costs are eligible for subsidies if at least 30 per cent greenhouse gas savings are achieved. This subsidy makes many projects not only ecologically but also economically highly attractive.

What advice would you give to companies that are now considering investing in large heat pump technology?

Andreas: My advice is clear: don't wait any longer. The technology is ready for the market, the subsidies are attractive, and the risks associated with fossil fuels are constantly increasing. Start by analysing your heat sources and sinks. Companies often find that they already have ideal conditions – whether through waste heat from existing processes or natural sources in the surrounding area. Our experts at ENGIE Refrigeration will support you in developing and implementing the optimal concept. Industry needs new heating solutions – quickly and on a scalable basis. Investing now not only gives you planning security, but also secures important competitive advantages.