Towards and oil-free future: our cooling and heating solutions

Oil-free or lubricated with oil? This is the question facing an increasing number of operating companies. With its QUANTUM and SPECTRUM series, ENGIE Refrigeration has demonstrated the benefits of oil-free operation in ground-breaking fashion while also identifying new ways to design future-proof chillers and heat pumps.

Your benefits from our oil-free systems

‘Our oil-free systems offer numerous advantages to operating companies around the world: oil-free operation means absolute safety, outstanding efficiency and high levels of sustainability – while saving time and money over the long term. That means our oil-free models fully cover the needs of the industrial, commercial, trade and service sectors. Both today and in the future.’

Daniel Keller, Head of Sales and Business Development

Arguments in favour of our oil-free systems

|

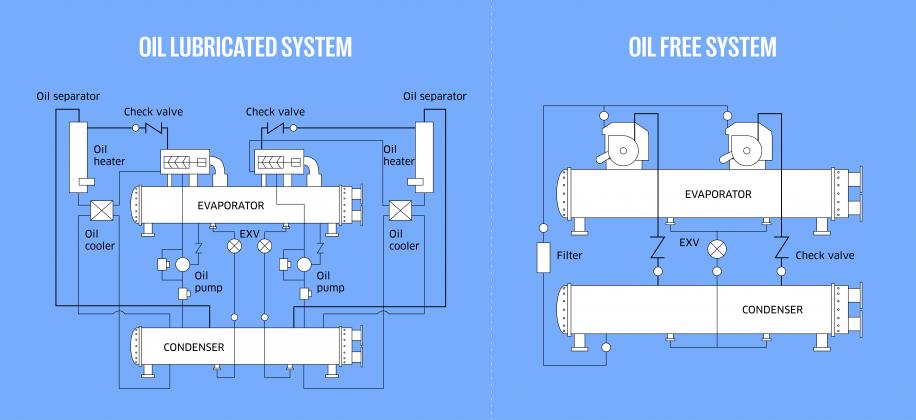

While oil-lubricated machines with piston, screw and scroll compressors are forced to rely on a steady supply of refrigerant-resistant oil, our QUANTUM and SPECTRUM models are completely oil-free thanks to their turbo compressor technology with magnetic bearings. As a result, efficiency-reducing oil deposits in the heat exchangers and refrigerant circuit (known as oil-fouling) are a thing of the past. Instead, operating companies benefit from constant performance and efficiency – throughout the machine’s entire service life. |

A working oil management system relies on numerous moving components. Oil pumps, oil receptacles and high-maintenance compressors are standard components of any oil-lubricated machine and considerably increase the machine’s susceptibility to faults – but that is not true for the QUANTUM or the SPECTRUM. Our series impress with a simple and low-maintenance machine design, and offer maximum efficiency even without oil. The result: lower maintenance costs, fewer service-related downtimes, and maximum operational reliability.

The QUANTUM and the SPECTRUM are one big step ahead of systems with common compressor technologies. This is because they operate entirely without lubricant oils that are hazardous to groundwater and are assigned to a Water Hazard Class (WHC) in line with the German Ordinance on facilities for handling substances that are hazardous to water (AwSV) and the Federal Water Act (WGH). As a result, they conserve resources at the best possible rate and easily master the challenge of climate neutrality – simply oil-free!

Leaks due to vibrations from machine components? Such leaks hardly ever occur in our oil-free machines. This is because the magnetic, contact-free bearing of the compressor shaft in the QUANTUM and the SPECTRUM keeps vibration and structure-borne noise levels to an absolute minimum.