Smartglasses in refrigeration technology

Smartglasses are increasingly being used as innovative aids in the world of work, and in refrigeration technology as well. This article describes the advantages smartglasses offer in the development of chillers and how we utilise them at ENGIE Refrigeration.

How smartglasses are used in the development of chillers

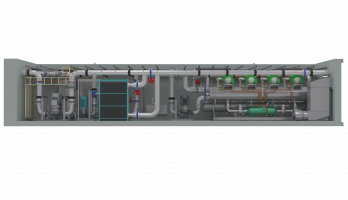

Smartglasses offer great potential in the development of chillers. In the past, all optimisations to our chillers were performed on computers. This had a major drawback, as chiller models are complex and sometimes very large. With traditional screens, it is often not possible to identify all the critical points in a chiller design. The result: potential improvements can be overlooked.

The use of smartglasses has considerably improved our optimisation processes. MR glasses allow us to walk around a chiller design and examine it from all sides. That means we can see every detail. Our engineers can even expand or shrink a virtual chiller at will within the room and move around inside the model. New ideas and approaches can thus be developed quickly.

Optimal testing processes thanks to smartglasses

Here at the company, teams from various departments such as design, project management and production are working together on improving chiller designs by means of smartglasses. A “master-slave mode” allows several wearers of smartglasses to examine a virtual chiller model together. Employees with slave smartglasses see the same details as the project manager with the master smartglasses. Additional viewers can join via a computer or projector. It has been demonstrated that our test processes with smartglasses are considerably more efficient than our previous workflows on the PC.

Smartglasses make it possible to examine a design more thoroughly for errors and to implement customers’ requests more quickly. “From my perspective, working with smartglasses will soon be the most important design method, for example when it comes to changing three-dimensional models from CAD computer-aided design systems,” says Jörn Stiegelmeier, head of technology and development at ENGIE Refrigeration.

Exciting applications in refrigeration technology

MR glasses make it possible to set up a chiller model in virtual form at its future place of deployment, such as a cold chamber, for example. This is a useful feature for the sales department. It is a good way to check the available space at the customer’s premises as well as potential connections for our chillers. Smartglasses also offer major advantages during service deployments and final approval: our support department in Lindau can supply technicians with important information while they are on site. Such information could include videos showing how to set up a chiller correctly, or work instructions that are shown on the smartglasses’ display.

What are smartglasses?

Smartglasses contain complex technology. They consist of an inward-facing screen and a powerful computer with a rechargeable battery. They can be put on with ear clips or a headband. We at ENGIE Refrigeration use so-called mixed-reality glasses (MR glasses). Smartglasses have a transparent display. The user can therefore see their actual surroundings as well as additional visual objects on the screen. These objects could be computer-generated 3D models of our chillers, for example. When the user changes their position and turns their head, takes a step forward or walks around the object, for example, the display is adapted accordingly – as if the virtual object was actually present in the room.