Process cooling: secure refrigeration for pharmaceutical companies

Process cooling plays an important role in many industries. It ensures that temperature-sensitive production processes are cooled precisely. This enables production processes to run smoothly, which in turn creates production reliability. Completely reliable refrigeration is also essential to the chemicals and pharmaceuticals industry. The production of medication requires complex production processes and relies on refrigeration technology that is of high quality, fail-safe, and also energy efficient.

Process cooling for medicine production

When it comes to precise temperature requirements, our QUANTUM chillers provide a highly recommendable solution. Their technology is based on extensive experience and plenty of know-how in matters of refrigeration. That is something our customers, such as the pharmaceuticals companies Nordmark Arzneimittel and Boehringer Ingelheim, appreciate. A major French customer in the pharmaceuticals industry has also recently chosen to rely on our refrigeration solutions. The company is operating the largest water-cooled QUANTUM models to date with the sustainable refrigerant R-1234ze and eight turbo compressors.

Know-how from ENGIE Refrigeration

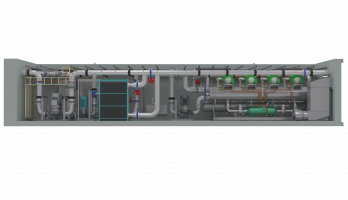

The implementation of process cooling requires careful preparation. The planning phase lasted several months. During this time, we examined the work processes on site in detail in order to develop the perfect refrigeration for the pharmaceuticals company. Since February 2019, the production hall of the medicine manufacturer has been operating three water-cooled QUANTUM chillers with the refrigerant R-1234ze. They run without oil, which saves on operating costs, and provide a refrigeration capacity of 2.4 megawatts each. The chillers were made at our production site in Lindau on Lake Constance and tested comprehensively before delivery.

Made in Germany: individual refrigeration technology made to measure

Daniel Keller, head of the sales support department at ENGIE Refrigeration, explains: “Our aim is to implement the best possible refrigeration solution for every process and meet our customers’ specific requirements with tailored concepts.” For our French customer we once again developed and successfully implemented an individual solution. The QUANTUM chillers are equipped with twin condensers for heat recovery. The company now utilises the waste heat generated in the production hall for other production processes. In addition, the company benefits from tax advantages. Like Germany, France offers subsidies for technical measures in the field of heat recovery.

Eco-friendly and energy-efficient process cooling

The refrigerant is R-1234ze, an environmentally friendly solution. This refrigerant has a GWP value of less than 1 and therefore produces an insignificant greenhouse effect. In combination with a special compressor design, R-1234ze also makes refrigeration particularly energy efficient. Last but not least, the multiple compressor design and double sensor system of the QUANTUM chiller ensure a high level of operational reliability during process cooling – ideal for use in the pharmaceutical industry.