QUANTUM P shows its full potential at chemicals industry giant

Erring on the side of caution – in the chemicals industry in particular, this is a number-one priority for many areas. One area that is highly sensitive is production. A German chemicals industry giant recently approached ENGIE Refrigeration to help fulfil its need for an industrial refrigeration system at its production site in Singapore – one characterised by absolute reliability. The solution: Five QUANTUM P chiller with a refrigeration capacity of 25 megawatts. This powerful system is not only perfectly reliable, but is also particularly energy efficient.

second production site in Singapore. Its objective: to satisfy the growing demand for a raw material for animal feed. The refrigeration system will play a key role in ensuring that the 300,000-ton annual production capacity the company is aiming for can, in fact, be achieved successfully. The highest possible level of supply reliability within the refrigeration system was therefore the key requirement that the group expected of the team at ENGIE Refrigeration. After all, an exact temperature is crucial to the quality of the chemical products being produced. Even minor variations can have an enormous impact, which is why refrigeration for such a sensitive area presents an enormous challenge. The situation is similar for refrigeration systems in the pharmaceuticals industry, in research institutes and laboratories, in hospitals and in data centres.

QUANTUM P uses sea water

Another challenge was encountered when working on the project on site in Singapore: due to the specific circumstances there, the chiller needed to be re-cooled using sea water. This is where the specialists from ENGIE Refrigeration benefited from their many years of experience in maritime refrigeration. It allowed them to offer an extremely corrosion-resistant version of the condenser, featuring internal pipes made of titanium.

Modular design of the chiller makes an impression

Five water-cooled QUANTUM chillers from the QUANTUM Power (QUANTUM P) series with a refrigeration capacity of 25 megawatts turned out to be the ideal solution. The modular design of the chiller, with five chilled water units, helps ensure that the refrigeration supply is reliable and is able to compensate for any additional, redundant chiller. This is something that none of our competitors can offer. And it is one of the precise reasons why our customer ultimately opted for ENGIE Refrigeration.

Highest level of reliability in refrigeration supply

Ten compressors arranged in parallel on the chiller increase the reliability of supply. The fact that each one can be isolated from the refrigeration circuit using shut-off valves allows them to be replaced individually, even while the other compressors are still operating. Furthermore, the QUANTUM P is supplied by two power feeds, which means that five compressors are assigned to one power supply respectively. If one power feed were to fail, 50 per cent of the refrigeration capacity of the entire unit would still remain available. In addition, all critical components within the sensor system and the expansion valves used for the individual compression stages have been installed twice, ensuring that the redundant component can cover the majority of the capacity requirements in the event of failure. In short, an innovative technological concept ensures that ENGIE Refrigeration can perfectly satisfy the stringent requirements expected of the refrigeration supply system with its QUANTUM-P chiller.

Refrigeration supply to boost efficiency

Along with reliability, the customer attaches key importance to the efficiency of the refrigeration system: the refrigeration manager ensures an energy-efficient refrigeration supply, because the chilled water sets form an intelligently connected network at every operating point. When operating under partial load in particular, this allows a very high level of energy efficiency to be achieved. This characteristic is a distinguishing feature of the water-cooled QUANTUM chillers.

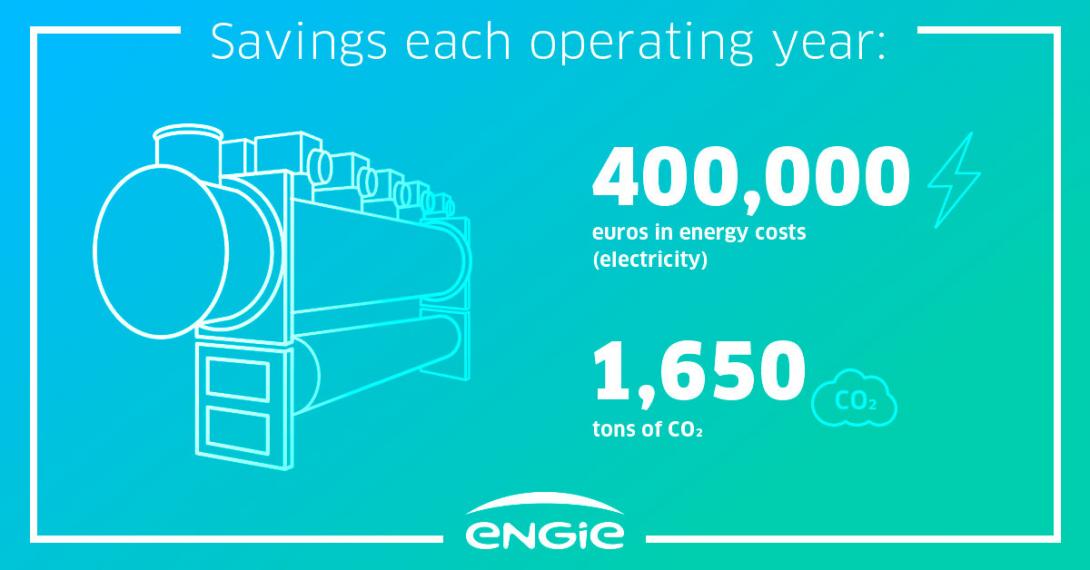

Cutting CO2 emissions by using QUANTUM P

The sophisticated system allows the chemicals industry company to benefit from huge savings as well. Each year it operates, it will help save 400,000 euros in energy costs (electricity) and therefore 1,650 tons of CO2 (basis of this calculation: 496 g of CO2 per kWh of electricity generated in Singapore). The QUANTUM-P chillers have been operating in the South East Asian island city-state for a few weeks now – and refrigeration is being supplied to the customer’s full satisfaction. That is why it is now working on new projects for ENGIE Refrigeration.