Ammonia for refrigeration systems: Potential and risks

Climate protection is currently at the heart of numerous political measures. These include the F-gas Regulation, which came into effect on 1 January 2015 and is designed to minimise the use of gases that are harmful to the environment. Consequently, the refrigeration and climate control industry is seeking out natural refrigerants that can provide an environmentally friendly alternative to refrigerants with a high GWP value (Global Warming Potential). Ammonia is such a natural refrigerant.

Ammonia for refrigeration technology has a long history

Ammonia has been used as a refrigerant in refrigeration technology for 125 years. Manfred Hofmann, expert and head of dka training at ENGIE Refrigeration, says: “NH3, or R717, is one of only a few climate-neutral refrigerants, in that it neither damages the ozone layer nor contributes to the greenhouse effect. Its ODP and GWP are 0.” It is also very cost-effective to operate chillers with ammonia. The natural refrigerant is easily available and has a high specific refrigeration capacity.

Ammonia – a natural refrigerant for commerce and industry

Refrigeration systems operated with ammonia are used around the world – mostly by businesses in the fields of commerce and industry. They include slaughterhouses, the chemicals industry, dairies, breweries and ice sports facilities. “Their refrigeration systems are operated either as direct evaporation systems, or separator systems, with refrigerant pumps or as indirect heat exchanger systems with primary refrigerant pumps and secondary chilled-medium pumps. The chilled medium is usually refrigerant, water, glycol or similar,” says Hofmann. Why is ammonia as a natural refrigerant not far more widely used? Well, next to its numerous environmental benefits it also involves several risks.

Operators have to meet stringent requirements

There are certain risks resulting from ammonia for refrigeration systems. Ammonia is classified as a Water Hazard Class 2 substance. This means that, if released, ammonia can be a danger to the immediate environment. Any business operating a chiller with ammonia is subject to strict legal requirements. Machine rooms, set-up locations and safety equipment must meet specific safety criteria. Hofmann adds: “In addition, ammonia systems may only be operated by specially trained personnel. The owner is responsible for ensuring this rule is observed.” The owner has to deal with a range of requirements, as the majority of NH3 refrigeration systems need to be supervised. Specially qualified personnel must conduct strict inspections and testing during commissioning and recommissioning, and must also produce thorough documentation of ongoing operations. In addition, every ammonia refrigeration system must be subjected to regular safety inspections and testing by a certified company; this includes leak checks and maintenance work as well as an inspection of the gas warning system, for example.

Ammonia refrigeration system: Strict regulations for machine rooms

Ammonia as a natural refrigerant should not be underestimated, which is why the set-up locations for NH3 chillers must comply with precise regulations.

- The ground must be sealed, and the room must be gas-tight.

- Only authorised personnel have access to the set-up location.

- Certain emergency and safety systems must be installed, such as emergency lighting and emergency ventilation with an independent power supply. In addition, any ammonia refrigeration system must allow operation via remote shut-off, also referred to as an emergency stop.

- There must also be a gas warning system with detectors and a power supply that is independent from the power grid of the emergency ventilation.

Hofmann stresses that, in spite of all these regulations, an investment in ammonia refrigeration technology is worth it. Ammonia refrigeration systems are constantly evolving, and are thus becoming increasingly more efficient and safe to operate.

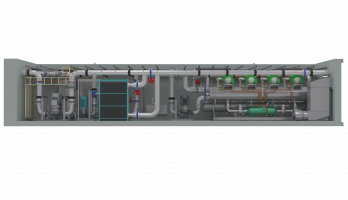

AMONUM made by ENGIE Refrigeration

The AMONUM series, suitable for a refrigeration capacity range of 50 to 250 kW, has been available from ENGIE since 2014. These chillers feature a sophisticated safety concept: A gas warning device can be set up inside the machine housing to detect even tiny leaks immediately. AMONUM chillers can also be set up in a machine room. With a housing of protection class IP54, they can be set up indoors and outdoors.

“But it gets even more convenient,” says Hofmann. “ENGIE Refrigeration offers traditional versions of the chillers, but it can also supply them in containers. Container systems are pre-mounted on a base frame and can thus be adapted quickly to the local conditions.” An ammonia refrigeration system in a container is a closed system. The container contains safety features such as escape route markings and a gas warning system. This makes things easier for the owner and allows the benefits of ammonia refrigeration technology to move into focus.