The PENSUM AIR – the chiller that sets new standards

The air-cooled PENSUM AIR chiller is far ahead of its time. Why? Future-proof refrigerant, higher energy efficiency, and a 78 per cent lower GWP value in comparison to R-410A – this is the chiller of the future.

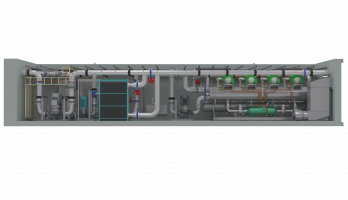

ENGIE Refrigeration is pursuing a specific target with its technological innovations: zero carbon. It is therefore part of the corporate philosophy to continuously improve the company’s chillers. As part of this process, the company has now relaunched its PENSUM AIR chiller, which has been on the market since 2013. It is available in four lines: Basic Cool, Free Cool, Super Silent and Reversible Heat, with a refrigeration performance between 50 and 400 kilowatts.

Innovative refrigerant reduces carbon emissions

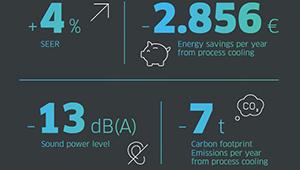

To meet the requirements of the F-gas Regulation, the aim is to reduce emissions of fluorinated greenhouse gases step by step. By 2030, the total amount of F-bases within the EU is to be lowered incrementally by 79 per cent. That is why the new PENSUM AIR runs on a more eco-friendly refrigerant than its predecessor model. The PENSUM AIR uses the refrigerant R-454B. Its excellent thermodynamic properties make it highly future-proof. It has a GWP value of 466, so it already meets the requirements of the F-gas Regulation. This regulation specifies that refrigerants must have an average GWP value below 500 from 2030. Compared to R-410A, the refrigerant that was used previously, R-454B can reduce the GWP value by 78 per cent – a milestone in refrigeration technology – without forfeiting refrigeration capacity and with an energy efficiency increase of up to 4 per cent. The PENSUM AIR already meets the Tier 2 Ecodesign Directive, which will apply from 2021.

Ready-to-use technology that delights!

The previous model was already extremely powerful, but it has been further refined and adapted to current requirements. Among other things, its configuration and design have been improved. The machine has also been equipped with a new compressor, which makes it even more efficient than its predecessor model. The four lines comprise up to 18 models in total, which are equipped with the minimum standard equipment at the factory. Each machine, for example, is equipped with additional structural safety measures to prevent the risk posed by a class ASHRAE A2L refrigerant. In addition, the housing has been improved and a protective grille has been installed in front of the fin-type heat exchanger to protect it from mechanical influences. Whether as a heat pump, with free cooling, super silent or just reliably cold: PENSUM AIR offers practical and attractive/sustainable/economical solutions for technological building services and process cooling.

Carefree all round thanks to the optimised PENSUM AIR

The outstanding equipment that the PENSUM AIR is fitted with at the factory can be optimised with the right add-ons. Customers can choose from various configuration packages, add maintenance packages and book other warranty and service options. After all, what distinguishes ENGIE Refrigeration is not just the quality of its technological products, but also its outstanding service – a carefree all-round package. With the PENSUM AIR, ENGIE Refrigeration is taking another important step on its path towards zero carbon. Office buildings, schools and other busy facilities can improve their ecological footprint with this chiller.