ARBURG relies on highly efficient QUANTUM chillers

ARBURG now runs three QUANTUM chillers from ENGIE Refrigeration. The company is based in Loßburg, Baden-Württemberg, and relies on the QUANTUM because energy efficiency and reliability are essential in machine production.

Reliable cooling for machine production

ARBURG is one of the world’s leading machine manufacturers, maintaining operations in more than 50 countries. Among other things, the company makes injection moulding machines and robot systems. One of ARBURG’s unique properties is its innovative freeformer system. This open system is used to produce functional components – to this end, qualified standard granulates are applied layer by layer, plastic drop by plastic drop. The company philosophy focuses on maximum quality standards and excellent service. ARBURG aims to supply its customers with their plastic products at minimal unit costs and highest quality. Efficiency and a focus on the customer’s perspective are two factors that ARBURG and ENGIE Refrigeration share.

Resource conservation as part of the mission statement

The machine production department at ARBURG runs highly-efficient QUANTUM chillers that provide optimal temperature. ARBURG attaches great value to environmental responsibility and sustainability. The QUANTUM chillers are therefore a perfect choice, as they offer first-class energy efficiency, even under partial loads. They are also equipped with twin condenser technology. This makes heat recovery possible for ARBURG: the majority of heat generated by refrigeration can be returned to consumers.

QUANTUM chillers: energy-efficient, powerful, quiet

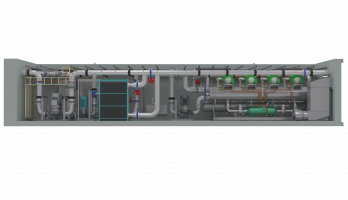

The manufacturer of injection moulding machines has been relying on the QUANTUM since 2015. At the time, ARBURG purchased an X030 type QUANTUM with a refrigeration capacity of 295 kW in order to replace the existing R22-operated chillers during the construction of a new building. The company subsequently added two X060 type QUANTUM chillers, which provide a refrigeration capacity of 600 kW each and feature twin condensers. They are run successively during ongoing operations. Special features of these QUANTUM chillers: they have front-facing control cabinets that facilitate access and accelerate servicing. They are also exceptionally quiet – an invaluable advantage, as ARBURG employees are working hard in their offices directly above the refrigeration centre.

Constant temperature level essential in some areas

ARBURG thus has three QUANTUM chillers that mainly cool the production processes. A constant temperature level is especially essential in measuring rooms and for grinders. However, building climate control is also important: employees need pleasant working conditions, and server rooms require reliable cooling. Refrigeration always generates waste heat – and a low-temperature heating circuit discharges it to consumers, such as the floor or façade heating.

QUANTUM: low-maintenance and energy-efficient in operation

It is a great compliment to us that a globally renowned machine manufacturer like ARBURG has chosen QUANTUM chillers from ENGIE Refrigeration. As well as supplying the technology to ARBURG, ENGIE Refrigeration also provided individual services. The QUANTUM chillers were fully integrated in the building control system – so that the parameters of the chillers are quick and easy to access. The QUANTUM chillers have been running flawlessly since their commissioning. And the energy efficiency of the machines has even improved over time: COP values have risen to 10 from their former level of 4.