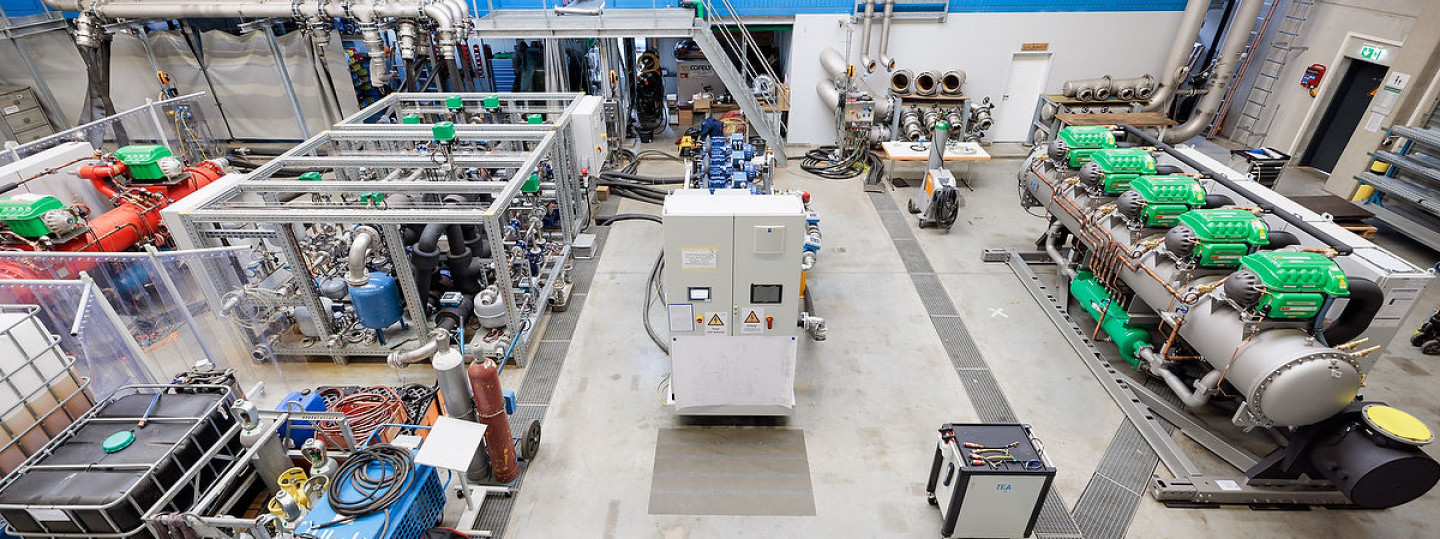

Our test benches for chillers and heat pumps

Performance, temperatures, pressure and flow rates – our five test benches thoroughly test the efficiency and performance of our chillers and heat pumps before delivery. We take care of each customer's specific requirements in advance so that you can concentrate on your core business when the machines are in operation.

Interesting facts about our test benches

Test, test and test again – that is our motto when it comes to the ideal chiller or heat pump. After all, we want to offer you, the operator, the very best. And for us, the best means high energy efficiency, innovative technology, high performance for chillers and heat pumps – and, last but not least, a partnership on equal terms.

To ensure this, a total of five test benches are installed at our Lindau headquarters, providing us with the technical support we need to design our cooling and heating solutions to best meet your requirements.

We use five test benches to test and optimise the performance of your chillers or heat pumps in advance:

- One test bench for our air-cooled chillers with a cooling capacity of up to 1.5 megawatts, on which we test the operation of continuous heat extraction (Green Heat Recovery) for sustainable waste heat utilisation.

- Two test benches for water-cooled chillers with a cooling capacity of up to 1.5 megawatts and a heating capacity of up to 1.9 megawatts.

- One test bench for water-cooled chillers with a cooling capacity of up to six megawatts and a heating capacity of up to 7.2 megawatts.

- One test bench for water/water heat pumps of the thermeco2 series for operation with heating water outlet temperatures of up to 125 °C.

In addition, it is possible to expand the two test benches for water-cooled chillers with up to 1.5 megawatts with an additional test facility for glycol chillers. These are suitable for systems with an outlet temperature of up to -20 degrees Celsius and a cooling capacity of up to 500 kilowatts.

On request, we also carry out measurements to determine structure-borne and air-borne noise on all our systems.

What are your advantages of real-time measurement of operating data on our test benches? There are several:

- You benefit from high energy efficiency, which is tested using innovative automation and control technology and proven in black on white.

- With us, you have a strong partner on equal terms who will accompany you on your journey towards your sustainability goals.

- Your chillers and heat pumps run with absolute operational reliability, as we ensure this through continuous testing.

- Our test benches are versatile in their simulation capabilities, enabling us to cover and optimise your specific scenario.

- You can expect a guaranteed reliable partnership with ENGIE Refrigeration.

Sounds great? It is great! We would be delighted if you would use our test benches to optimise the performance of your chillers and heat pumps in the long term.